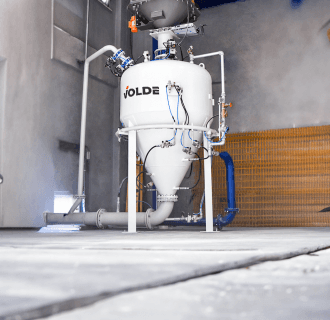

PVC and Calcite Silo Systems

Secrets Hidden in Silos

At VOLDE, we aim to enhance the efficiency and product quality of your PVC compound production process with our PVC and calcite silo systems. These systems are designed to ensure the safe and efficient storage of PVC and calcite, facilitating the management of compound production processes.

For the seamless integration of PVC and calcite powders used in PVC compound production into the production process, safe and orderly storage is required. These systems guarantee the accurate and timely feeding of raw materials to the production lines.

Fully Automated Storage

Calcite arriving at the facility by silo truck is directly pumped into the silos. PVC powder arriving in big bags is filled into the silos using the FREEBAG system and the DENSPLUS dense phase conveying system. All silos are equipped with filters, pressure safety valves, and level sensors necessary for automation. This ensures that the storage process is managed fully automatically and that raw materials are fed correctly and continuously to the production lines.

Efficiency with PVC and Calcite

At VOLDE, our PVC and Calcite Silo System ensures high efficiency and excellent product quality in PVC compound facilities. Our systems provide fully automated control, reliable dosing, and high efficiency in production processes.