Powder Pneumatic Conveying

Superior Performance in Raw Material Flow

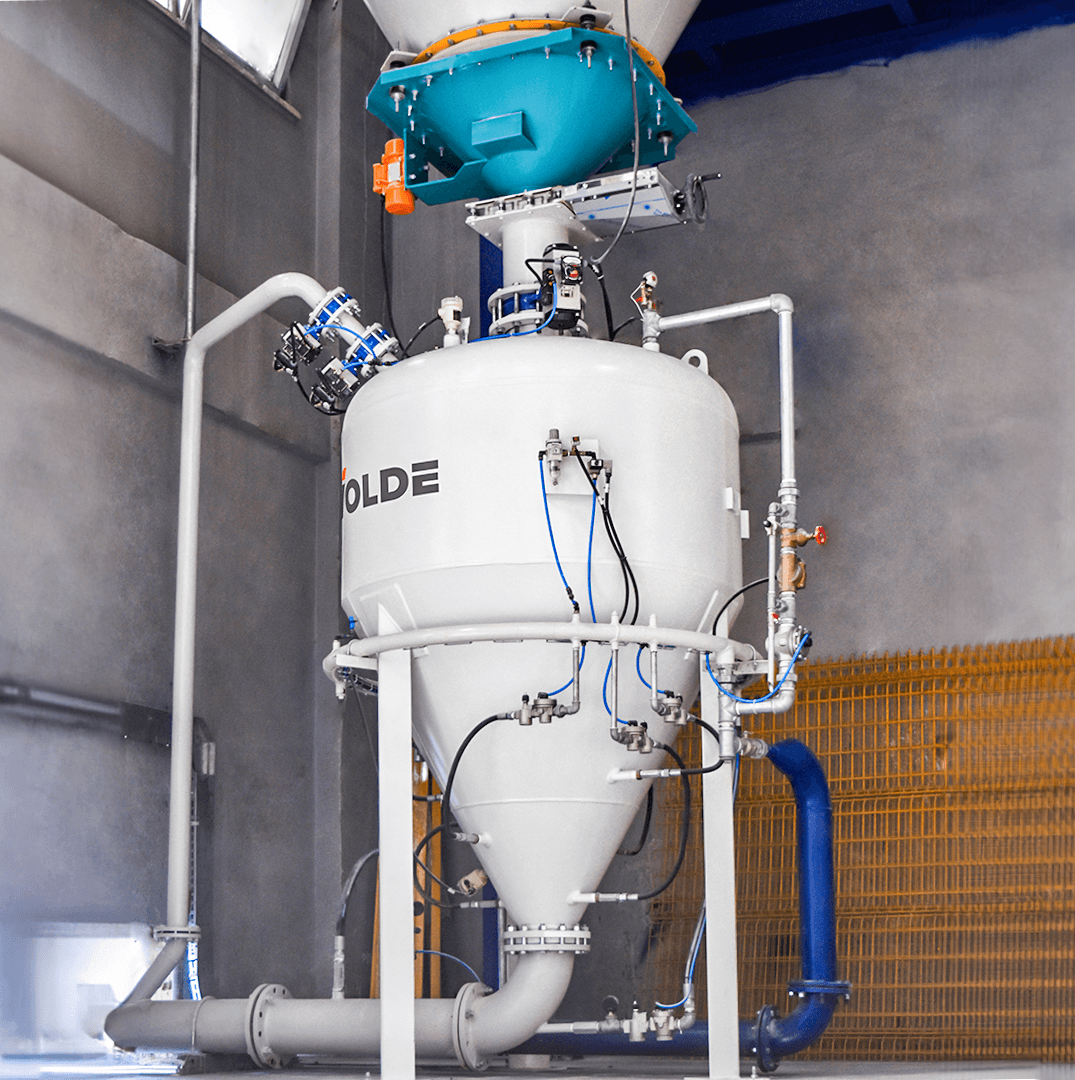

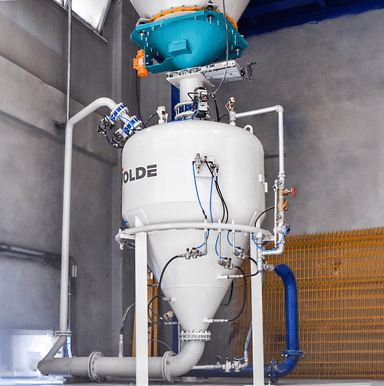

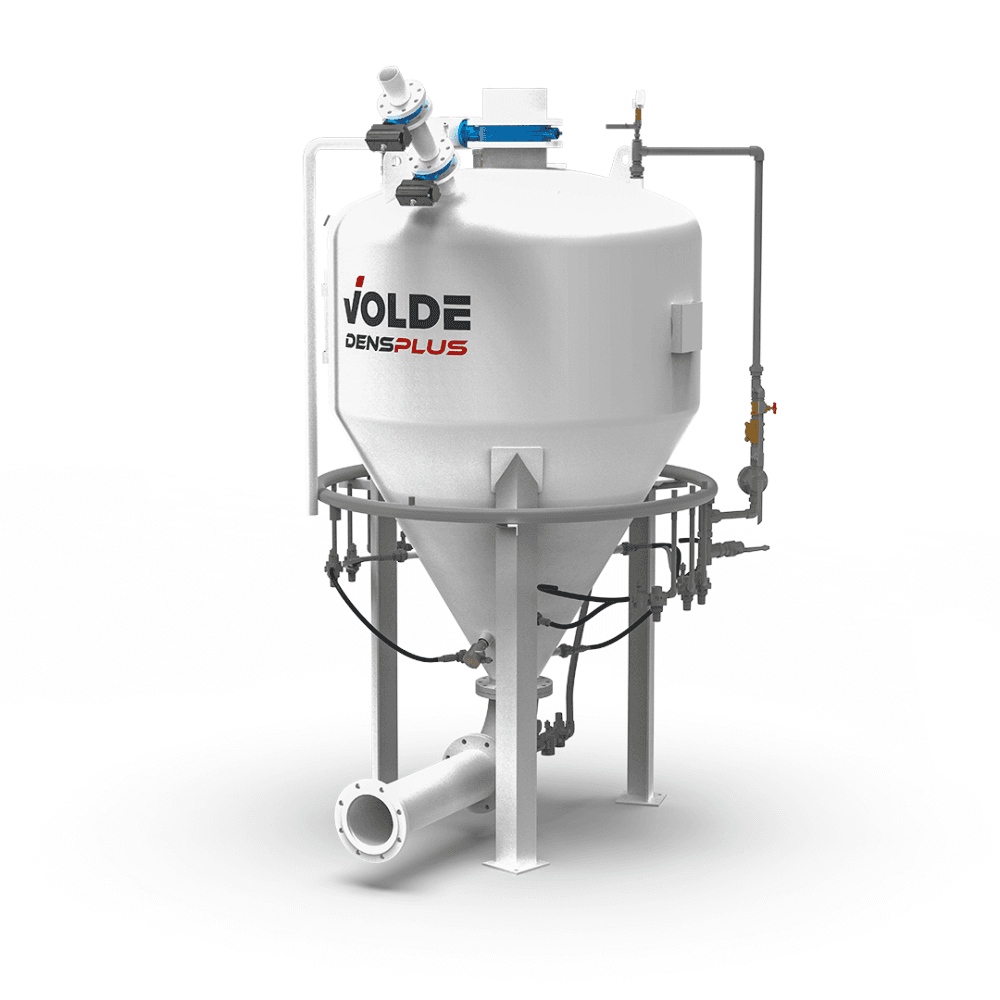

At Volde, we provide advanced systems for the pneumatic conveying of soda and sulfate powders used in detergent production processes. This system ensures the safe storage of critical raw materials like soda and sulfate powders in detergent production facilities and their pneumatic transfer to daily silos. By automating material flow, this system ensures your production process is safe and efficient.

This system ensures the effective storage of soda and sulfate powders used in detergent production processes in your facility and their safe pneumatic transfer to daily silos as needed. By eliminating disruptions in your production processes, this system enhances operational efficiency.

Taking Control of Dust

The system consists of three 150 m³ capacity weighing silos. These silos can be filled either by silo trucks or, in cases of supply issues, using the FREEBAG big bag unloading system. Each silo, equipped with the DENSPLUS dense phase conveying system, can pneumatically transfer 30 tons of soda and 36 tons of sulfate per hour to the daily silos. All these processes are managed automatically through our SCADA system, ensuring operational efficiency and the accurate use of raw materials.

The Safe Journey of Soda and Sulfate

At Volde, we ensure the safe and effective management of raw materials with our specially designed Soda and Sulfate Silo and Conveying Systems for detergent production facilities. Our Soda-Sulfate Silo and Pneumatic Conveying System optimizes not only material management but also every aspect of your production process.