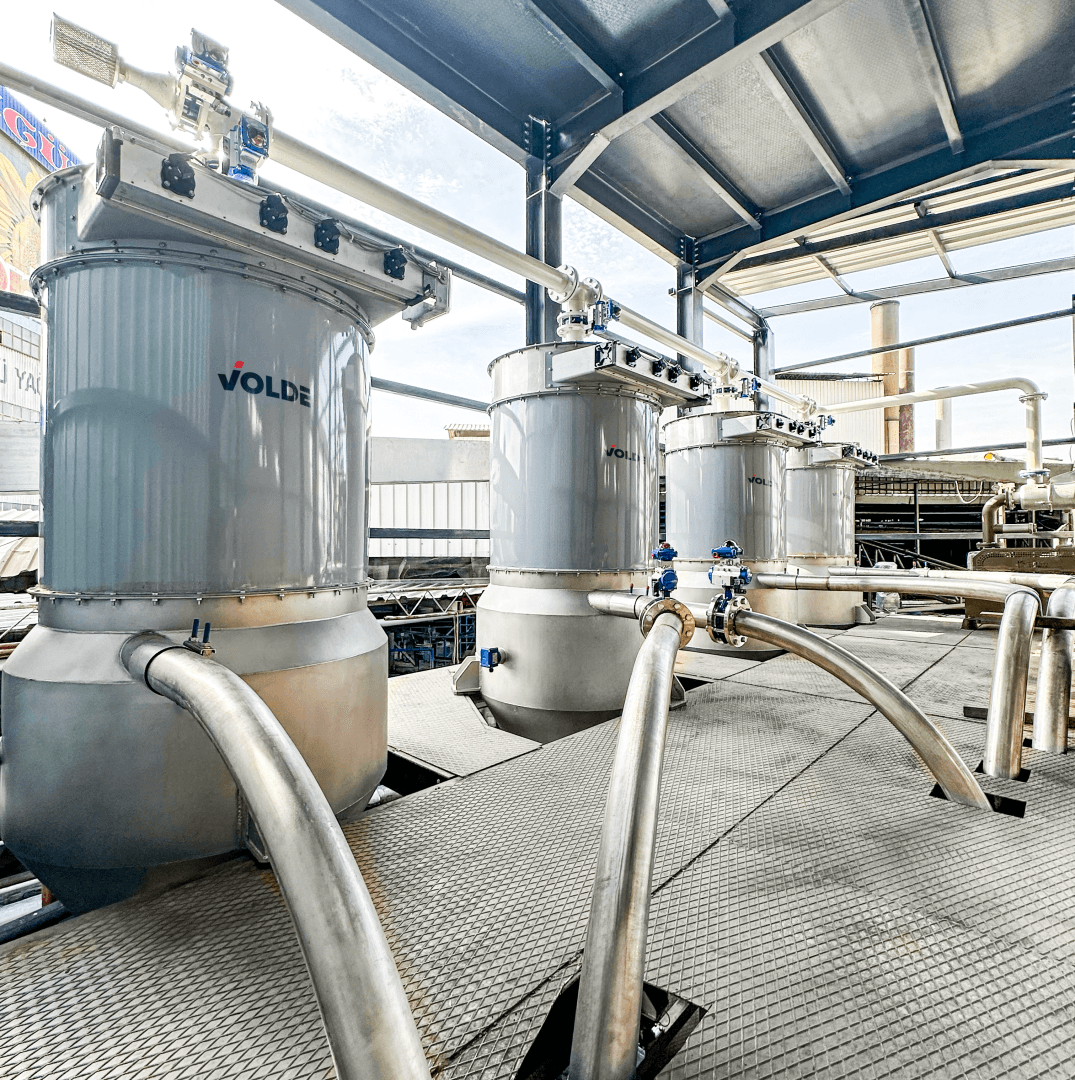

Oil Bleaching Plant

The Heartbeat of Liquid Oil Production

At VOLDE, we offer specially designed bentonite conveying and dosing systems to enhance the quality and efficiency of the bleaching process in liquid oil production facilities. This system ensures the precise and effective dosing of the bentonite powder necessary for the bleaching process, thereby maximizing product quality.

The primary goal of our system is to ensure the accurate and efficient dosing of bentonite powder used in the bleaching process at liquid oil production facilities. This system contributes to maximizing product quality by ensuring the continuous and efficient integration of bentonite powder into the production process.

Master of Oil Bleaching

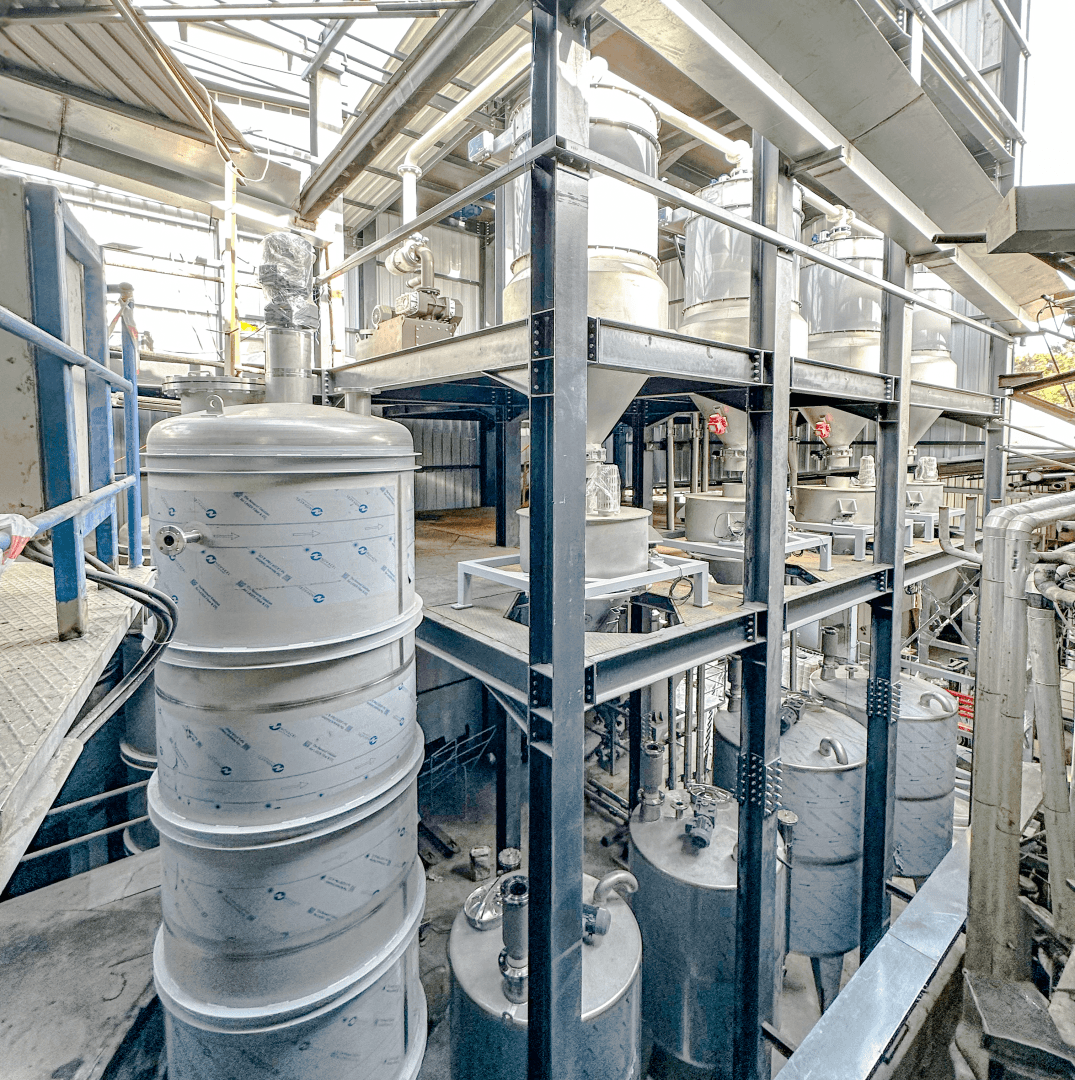

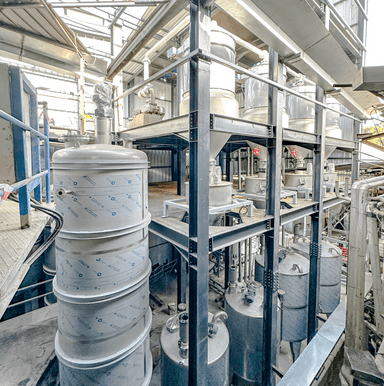

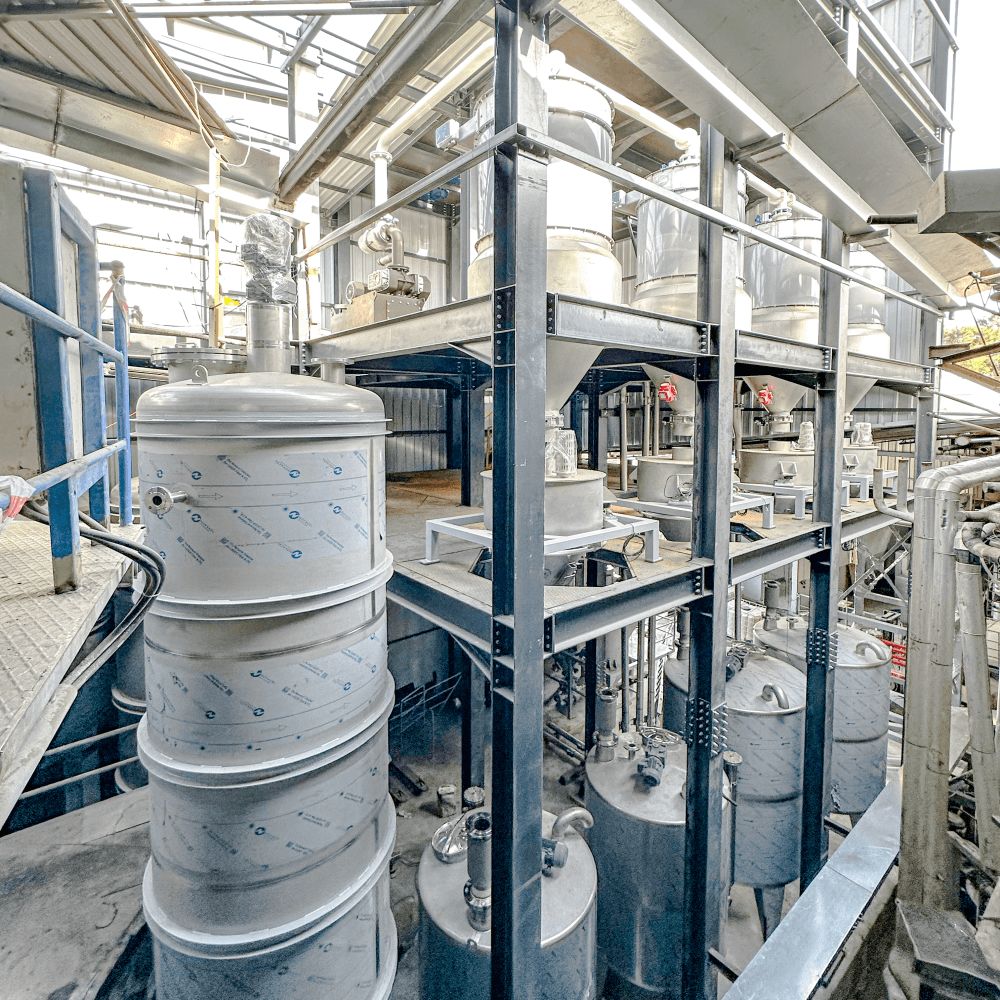

Various types of bentonite coming from big bags and sacks are introduced into the production process through FREEBAG and bag dumping hoppers. Conveyed over four production tanks by the VACUMATE vacuum conveyance system, the bentonite is continuously dosed into mixing tanks with the aid of gravimetric feeders. The dosage amount is automatically and instantly adjusted according to the production capacity coming from the main line, ensuring an continued and proper feed.

Processes Filled with Efficiency

The VOLDE bentonite conveying and dosing system is designed to enhance efficiency and product quality for liquid oil production facilities. Our bentonite conveying and dosing system ensures the precision and efficiency required in the bleaching process, thus improving the quality of liquid oil production.