Compound Extruder Feeding

Optimized Flow

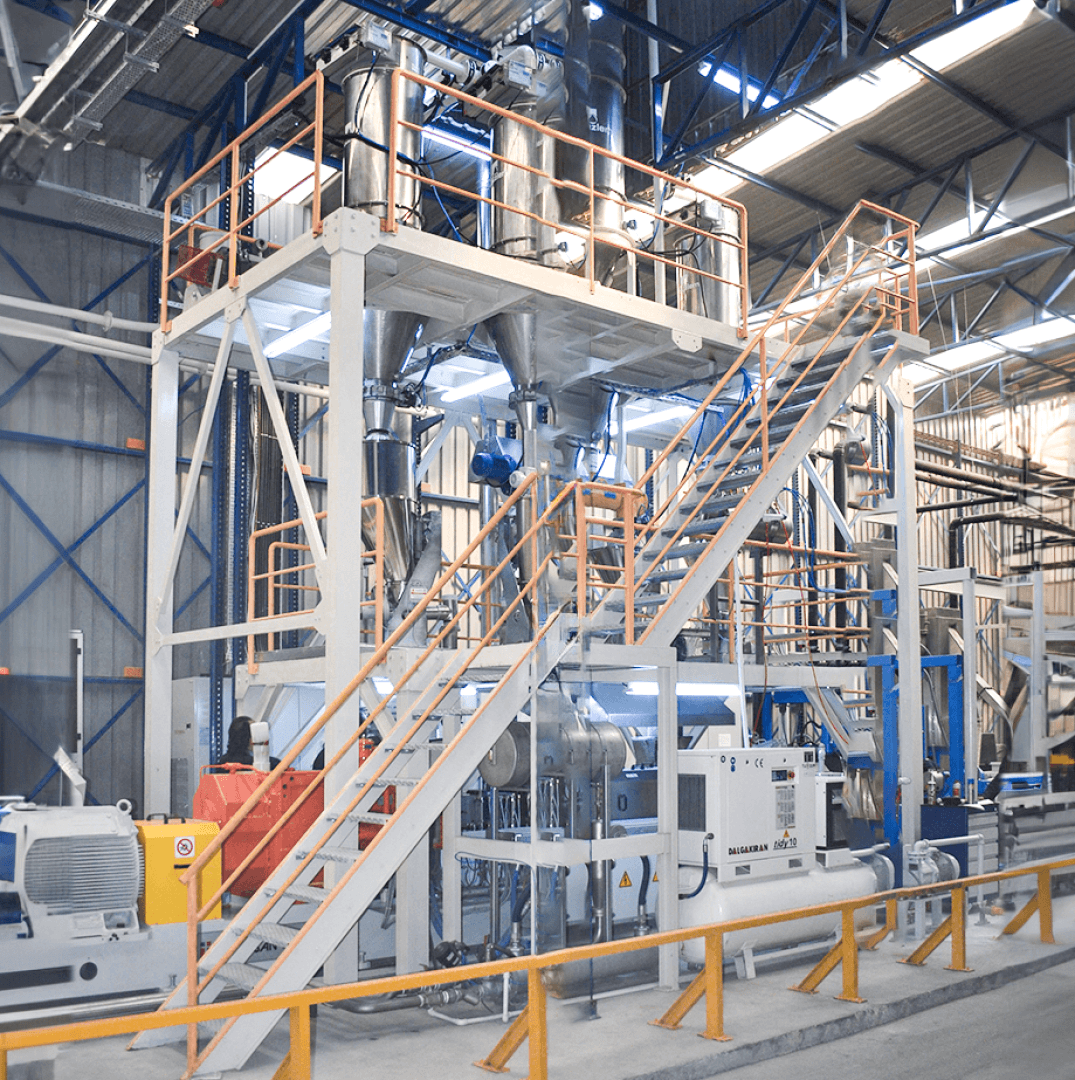

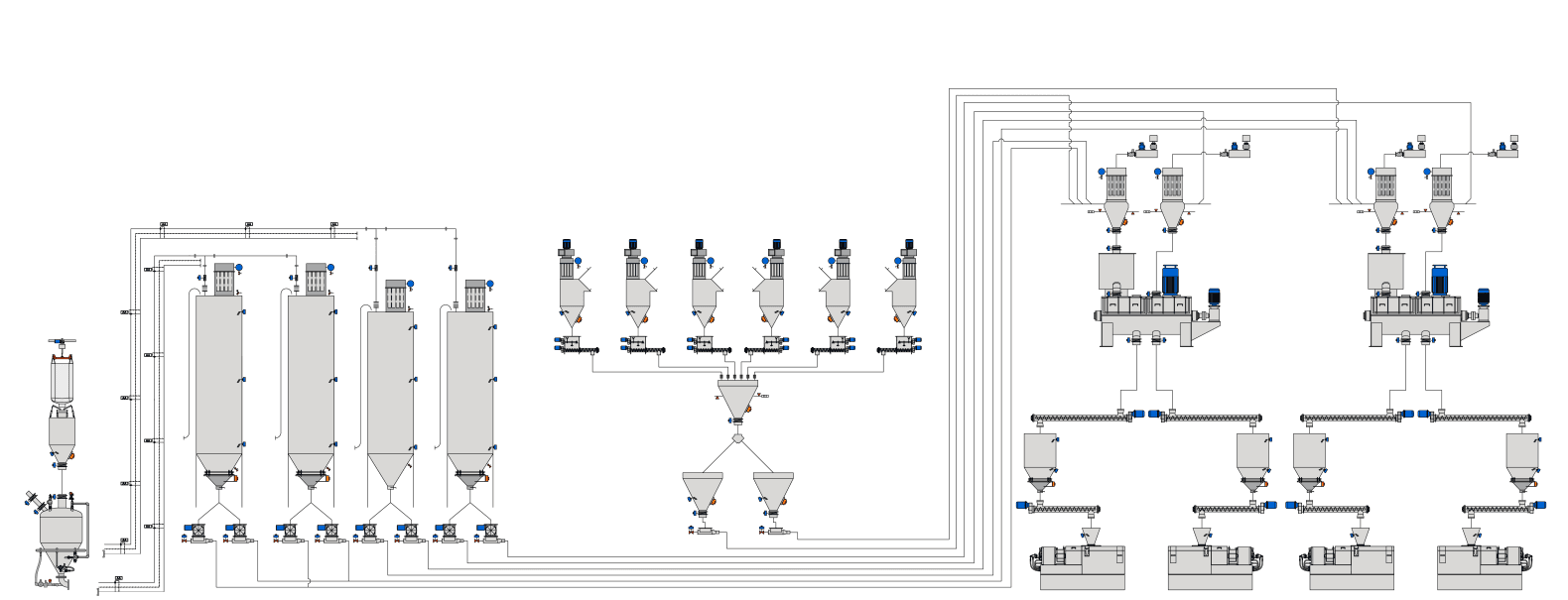

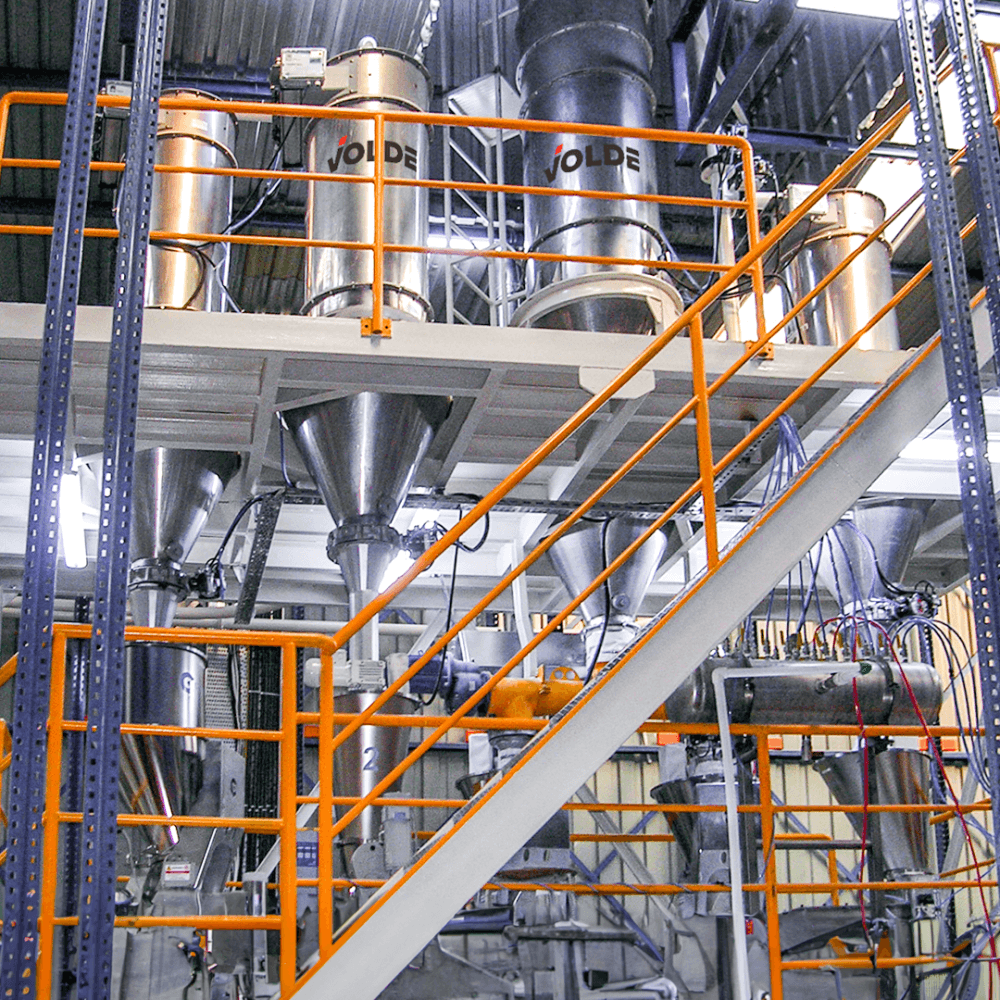

At VOLDE, we aim to enhance the efficiency and product quality of your production process with our Compound Extruder Feeding System, designed for the seamless and efficient feeding of fiberglass-filled compounds in plastic pipe and fittings manufacturing facilities. This system ensures the flawless transportation and feeding of materials, maintaining the continuity of your production process and improving product quality.

The Compound Extruder Feeding System is designed to ensure the precise and accurate feeding of PE, fiberglass, and other additives into the extruder at plastic pipe and fittings facilities. This system guarantees the correct ratios and continuous feeding of materials to the extruder, enabling the production of high-quality compounds.

Precise Feeding, Perfect Product

PE, fiberglass, and additive granules arriving in big bags are transported to the bunkers using the VACUMATE vacuum conveying system. The raw materials transported to the bunkers are discharged based on signals from gravimetric feeders, ensuring the feeders operate continuously. The granules produced in the extruder are conveyed by the VACUMATE vacuum system and filled into big bags using the FULLBAG big bag filling system.

Compound Transformation

At VOLDE, we optimize our customers' production processes with customized Compound Extruder Feeding Systems designed for plastic pipe and fittings facilities. Our compound extruder feeding systems ensure the precision and reliability needed in your production processes.