Perlite Lightweight Concrete Plant

Superior Plaster Solutions with the Power of Perlite

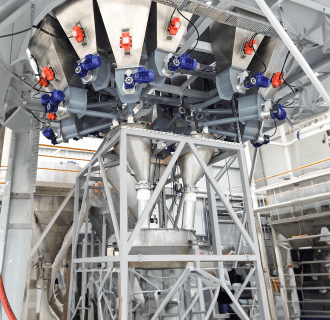

At Volde, we aim to optimize the production process for manufacturers of perlite plaster with our continuous dosing system. This system ensures the precise dosing and feeding into the mixer of 16 different raw materials used in perlite plaster production with minimal breakage.

In the perlite plaster production facility, the mixture of 16 different raw materials, including expanded perlite, is continuously and precisely dosed and fed into the mixer. This system aims to achieve a high-quality and homogeneous mixture.

Precision Craftsmanship in Plaster Production

In the facility, 16 different raw materials, including expanded perlite, are stored in silos and bunkers. The raw materials are precisely weighed and dosed with our FEEDGRAM feeders, according to the special recipe selected via the SCADA system, ensuring no breakage occurs. This highly precise weighing and dosing process allows the mixture to be fed into the continuous mixer via a bucket elevator. This ensures that the production process continues seamlessly and efficiently.

Precise Mixtures, Solid Structures

With our continuous dosing system implemented for perlite plaster production facilities, we are leading the way in innovative solutions in the industry. This system not only enhances the quality of our customers' products but also maximizes the efficiency and sustainability of their production processes. By offering innovative solutions, we help you increase the efficiency of your production processes and improve product quality. Our continuous dosing system guarantees precision and high quality in perlite plaster production.